Doublepane 1 7 3

War thunder catalina mac. There is a table of building material R-Values further down in this article, but first we should quickly cover some basics about R-Values, U-Factors, and calculating thermal resistance.

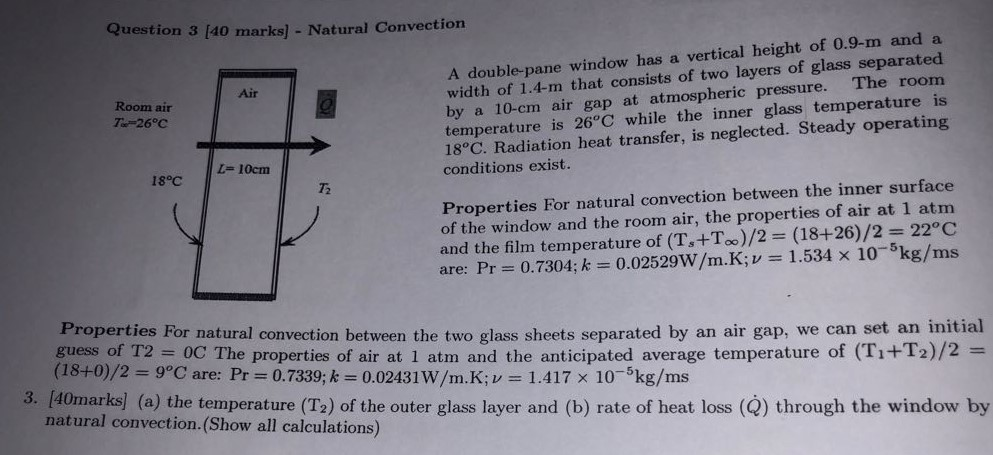

Phasize the Andersen ® brand name and triangle (figure 7). Use of a la-ser provided crisper images. NFRC codes were added to identify product line. The HP version (for example,.7) was moved from behind the date code (CIG-3 2-02.7) to behind the plan code (CIG-3.7 2-02). 2004–Present In the 3rd quarter 2004, logo artwork was changed. Double-pane windows have an R-value ranging from 3 to 3.8, while triple-paned windows have an R-value of up to 7- 8, making them more effective at blocking heat flow. This means that replacing double-paned units with triple-paned windows reduces heating costs. A vertical 1.5-m-high, 2.8-m-wide double-pane window consists of two layers of glass separated by a 2.0-cm air gap at atmospheric pressure. The room temperature is 26°C while the inner glass temperature is 18°C. Disregarding radiation heat transfer, determine the temperature of the outer glass layer and the rate of heat loss through the.

What are R-values?

Macbooster 7 2 2. In construction, the R-value is the measurement of a material's capacity to resist heat flow Adware zap pro 2 7 0 0. from one side to the other. In simple terms, R-values measure the effectiveness of insulation and a higher number represents more effective insulation.

R-values are additive. For instance if you have a material with an R-value of 12 attached to another material with an R-value of 3, then both materials combined have an R-value of 15. Marked 2 5 11 – easily preview your markdown documents.

R-value Units

As we said before, the R-value measures the thermal resistance of a material. This can also be expressed as the temperature difference that will cause one unit of heat to pass through one unit of area over a period of time. In the equation below, the imperial units are shown on the left and the SI units are shown on the right.

What are U-factors?

Many energy modeling programs and code calculations require U-factors (sometimes called U-values) of assemblies. https://downofiles143.weebly.com/geekbench-4-4-2-3.html. The U-factor is the heat transfer coefficient, which simply means that is is a measure of an assembly's capacity to transfer thermal energy across its thickness. The U-factor of an assembly is the reciprocal of the total R-value of the assembly. The equation is shown below.

Tables of Building Material R-values

The R-values for specific assemblies like doors and glazing in the table below are generalizations because they can vary significantly based on special materials that the manufacturer uses. For instance, using argon gas in a double pane insulating glass unit will dramatically improve the R-value. Consult manufacturer literature for values specific to your project.

Double Pane 1 7 30

| Material | Thickness | R-value (F° · sq.ft. · hr/Btu) |

|---|---|---|

| Air Films | ||

| Exterior | 0.17 | |

| Interior Wall | 0.68 | |

| Interior Ceiling | 0.61 | |

| Air Space | ||

| Minimum 1/2' up to 4' | 1.00 | |

| Building Board | ||

| Gypsum Wall Board | 1/2' | 0.45 |

| Gypsum Wall Board | 5/8' | 0.5625 |

| Plywood | 1/2' | 0.62 |

| Plywood | 1' | 1.25 |

| Fiber board sheathing | 1/2' | 1.32 |

| Medium Density Particle Board | 1/2' | 0.53 |

| Insulating Materials | ||

| R-11 Mineral Fiber with 2x4 metal studs @ 16' OC | 5.50 | |

| R-11 Mineral Fiber with 2x4 wood studs @ 16' OC | 12.44 | |

| R-11 Mineral Fiber with 2x4 metal studs @ 24' OC | 6.60 | |

| R-19 Mineral Fiber with 2x6 metal studs @ 16' OC | 7.10 | |

| R-19 Mineral Fiber with 2x6 metal studs @ 24' OC | 8.55 | |

| R-19 Mineral Fiber with 2x6 wood studs @ 24' OC | 19.11 | |

| Expanded Polystyrene (Extruded) | 1' | 5.00 |

| Polyurethane Foam (Foamed on site) | 1' | 6.25 |

| Polyisocyanurate (Foil Faced) | 1' | 7.20 |

| Masonry and Concrete | ||

| Common Brick | 4' | 0.80 |

| Face Brick | 4' | 0.44 |

| Concrete Masonry Unit (CMU) | 4' | 0.80 |

| Concrete Masonry Unit (CMU) | 8' | 1.11 |

| Concrete Masonry Unit (CMU) | 12' | 1.28 |

| Concrete 60 pounds per cubic foot | 1' | 0.52 |

| Concrete 70 pounds per cubic foot | 1' | 0.42 |

| Concrete 80 pounds per cubic foot | 1' | 0.33 |

| Concrete 90 pounds per cubic foot | 1' | 0.26 |

| Concrete 100 pounds per cubic foot | 1' | 0.21 |

| Concrete 120 pounds per cubic foot | 1' | 0.13 |

| Concrete 150 pounds per cubic foot | 1' | 0.07 |

| Granite | 1' | 0.05 |

| Sandstone / Limestone | 1' | 0.08 |

| Siding | ||

| Aluminum / Vinyl (not insulated) | 0.61 | |

| Aluminum / Vinyl (1/2' insulation) | 1.80 | |

| Flooring | ||

| Hardwood | 3/4' | 0.68 |

| Tile | 0.05 | |

| Carpet with fiber pad | 2.08 | |

| Carpet with rubber pad | 1.23 | |

| Roofing | ||

| Asphalt Shingles | 0.44 | |

| Wood Shingles | 0.97 | |

| Glazing | ||

| Single Pane | 1/4' | 0.91 |

| Double Pane with 1/4' air space | 1.69 | |

| Double Pane with 1/2' air space | 2.04 | |

| Double Pane with 3/4' air space | 2.38 | |

| Triple Pane with 1/4' air spaces | 2.56 | |

| Triple Pane with 1/2' air spaces | 3.23 | |

| Doors | ||

| Wood, solid core | 1 3/4' | 2.17 |

| Solid insulated metal door, polystyrene insulation ASTM C518 Calculated | 1.5' - 2' | 6.00 - 7.00 |

| Solid insulated metal door, polystyrene insulation ASTM C1363 Operable | 1.5' - 2' | 2.20 - 2.80 |

| Solid insulated metal door, polyurethane insulation ASTM C518 Calculated | 1.5' - 2' | 10.00 - 11.00 |

| Solid insulated metal door, polyurethane insulation ASTM C1363 Operable | 1.5' - 2' | 2.50 - 3.50 |

The values in the table above were taken from a number of sources including: the ASHRAE Handbook of Fundamentals, ColoradoENERGY.org, and Building Construction Illustrated by Francis D.K. Ching. Other minor sources were also used. Archtoolbox does not test materials or assemblies.

Double Pane 1 7 35

Doors and Assemblies

In the chart above, you will notice that there are two vastly different R-values provided for insulated metal doors with polyurethane insulation. Based on ASTM C518 (Calculation Method) the door has an R-value of up to 11, but using ASTM C1363 (Tested/Operable) the same door only have an R-value of up to 3.5. This is a huge difference and essentially comes down to ASTM C518 being a theoretical maximum based on a steady-state thermal test of only a portion of the door panel. However, we all know that the frame, gasketing, and, hardware will significantly affect the thermal transmittance. Lightwave 3d 2018 0 4 – 3d animation software freeware. So a new standard test has been implemented, ASTM C1363, which tests the entire door assembly including the frame and hardware.

The results of ASTM C1363 are much lower, but are much more accurate to the actual installed conditions. In fact, the doors are performing the same as before – it is just that the R-values are much more in line with how the door really performs. Loopback 1 1 8 – route audio between applications free. Many architects are now specifying doors with the ASTM C1363 test as the standard for thermal transmittance. It is expected that other products will follow suit.

Double Pane 1 7 32

For more information, check out the Steel Door Institute's article Why Have Thermal Performance Ratings Changed?

Doublepane 1 7 3

UNDER MAINTENANCE